GET LESS - Less Waste - Less Labor - Less Time.

For over a decade, SpecMETRIX - Sensory Analytics has been solely focused on acquiring and delivering previously unattainable process control and coating quality data to support global manufacturing leaders. The longstanding limitations with existing measurement methods for coating thickness and film weight process control made us recognize the potential for dramatic improvements.

partner specmetrix indonesia

Industrial Applications of SpecMETRIX Systems

- Metal Coils

- Industrial Coating

- Flexible Packaging

- Metal Packaging

- Automotive

- Aerospace & Defense

Less Waste - Less Labor - Less Time

Industrial Applications of SpecMETRIX Systems

- Metal Coils

- Industrial Coating

- Flexible Packaging

- Automotive

- Aerospace & Defense

SpecMetrix systems are available as flexible off-line and ruggedized in-line non-contact coating measurement tools. These patented and proprietary innovations have enabled our SpecMetrix measurement system to be uniquely able to measure nearly all applied wet or dry coatings over the widest variety of substrates and end-products. partner specmetrix indonesia

Offline lab tools

Designed to streamline QA processes

Our SpecMetrix lab systems can provide simultaneous thickness measurement of single or dual coatings or discrete film layers on flat samples and component parts in real-time. This ultra-precise and instant measurement capability accelerates sample testing data collection.

All SpecMetrix offline configurations are measurement ready for wet or dry samples in any environment from the QA lab to the factory floor. This flexibility allows for easy and accurate coat weight and absolute thickness checks during set-ups or sample testing.

partner specmetrix indonesia

Offline Lab Tools

Our SpecMetrix lab systems can provide simultaneous thickness measurement of single or dual coatings or discrete film layers on flat samples and component parts in real-time.

All SpecMetrix offline configurations are measurement ready for wet or dry samples in any environment from the QA lab to the factory floor. This flexibility allows for easy and accurate coat weight and absolute thickness checks during set-ups or sample testing.

Metal Coil

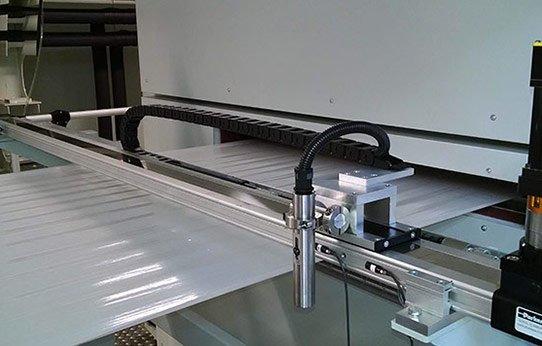

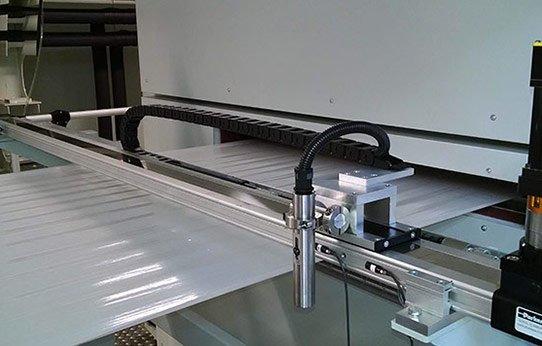

For in-process coil coating measurement applications, both fixed probe and scanning system configurations are offered to meet QA needs. Our in-line system designs are flexible for simultaneous top and bottom coating applications with multiple fixed probes. Our traversing measurement configuration options allow in-process, cross-and-down coil QA analysis. Plant teams can select whatever pattern is best suited for their production requirements.

Metal Coil

Unprecedented accuracy in coating thickness measurement on coils and flat sheets. For in-process coil coating measurement applications, both fixed probe and scanning system configurations are offered to meet QA needs.

Our in-line system designs are flexible for simultaneous top and bottom coating applications with multiple fixed probes. Our traversing measurement configuration options allow in-process, cross-and-down coil QA analysis. Plant teams can select whatever pattern is best suited for their production requirements. The ability to provide full side to side primer, top coat or other coating thickness measurements of coated coils delivers unmatched QA process improvements to meet plant team needs.

partner specmetrix indonesia

Flexible Packaging

Our non-contact and non-hazardous systems produce instant, actionable data for a wide range of film and web applications.

As a result, SpecMetrix systems provide more valuable real-time process control and quality assurance to manufacturing and QA teams. Operators obtain immediate feedback on coating quality while providing plant management with direct quality results without any operator involvement—saving time, labor and money.

partner specmetrix indonesia

more..

Metal Packaging

Our lab, QA station and ACS systems are in active use at global beverage and food OEMs, who use them as an incoming inspection tool to verify supplier container quality or diagnose potential film weight or coating thickness problems on samples or individual containers. Other food and beverage manufacturers integrate our SpecMetrix in-line measurement systems to directly measure wet coatings on their production lines to get continuous real-time data that streamlines set-up, changeover and inspection times and also reduces coating costs.

partner specmetrix indonesia

more..